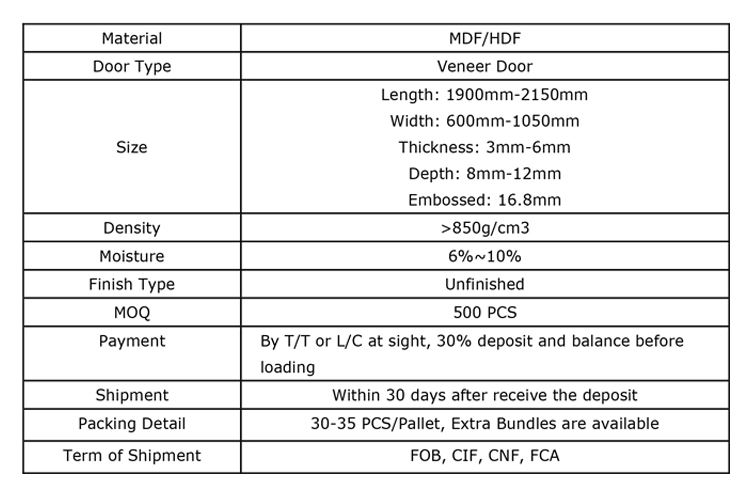

JHK-004 4 Panel Hollow Core Interior Veneer Doors

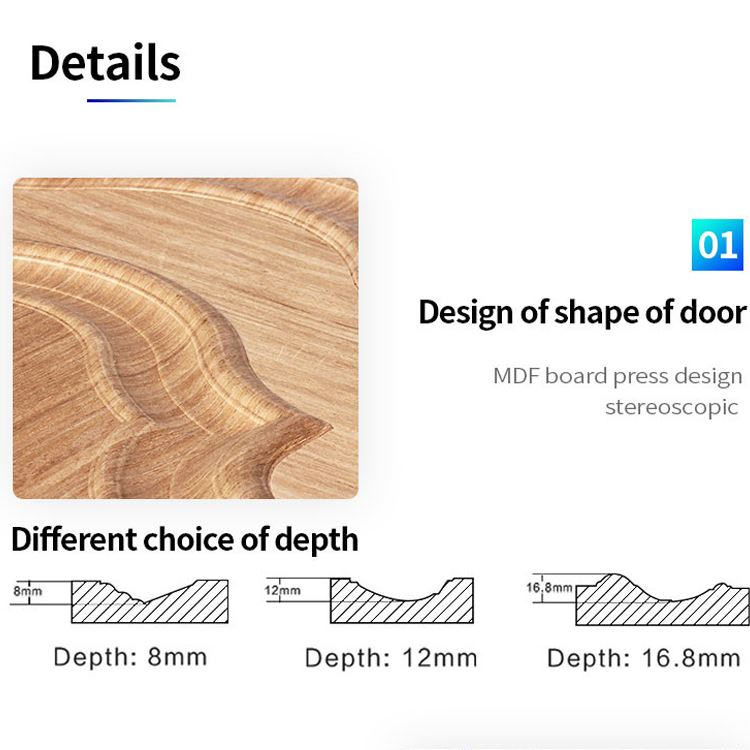

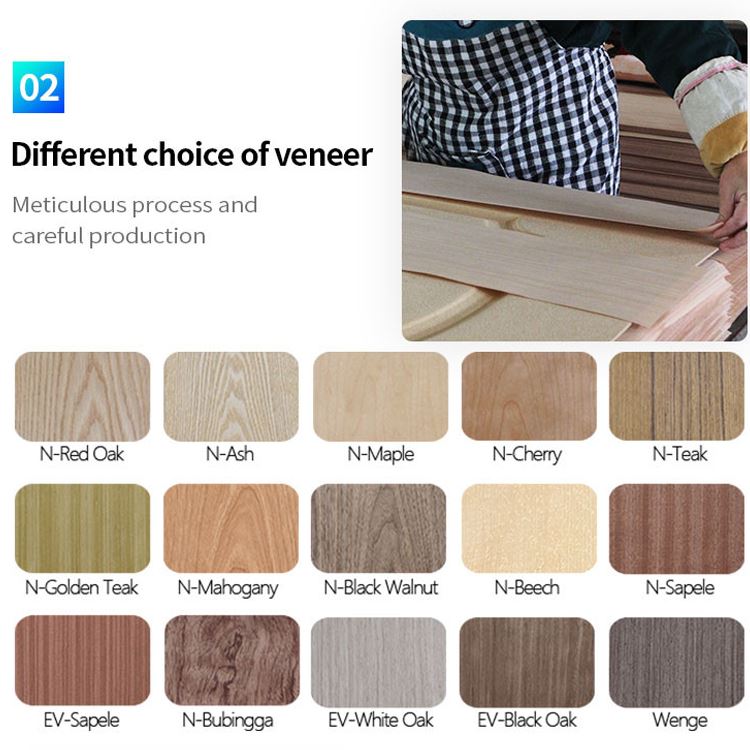

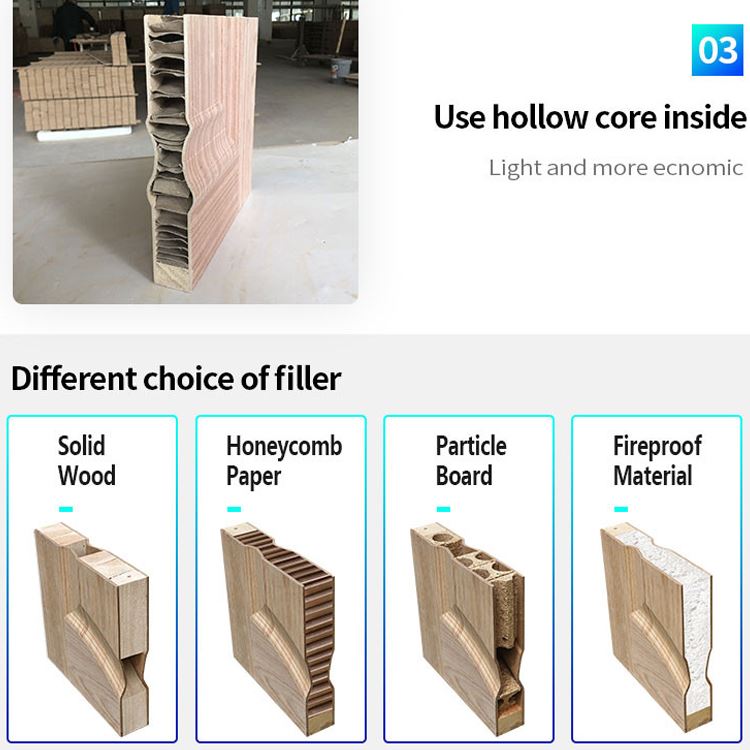

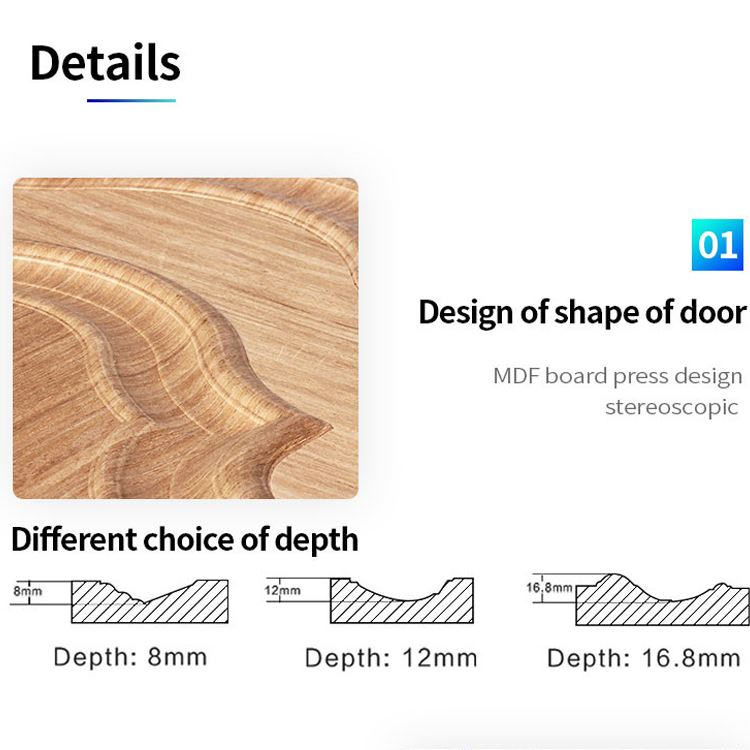

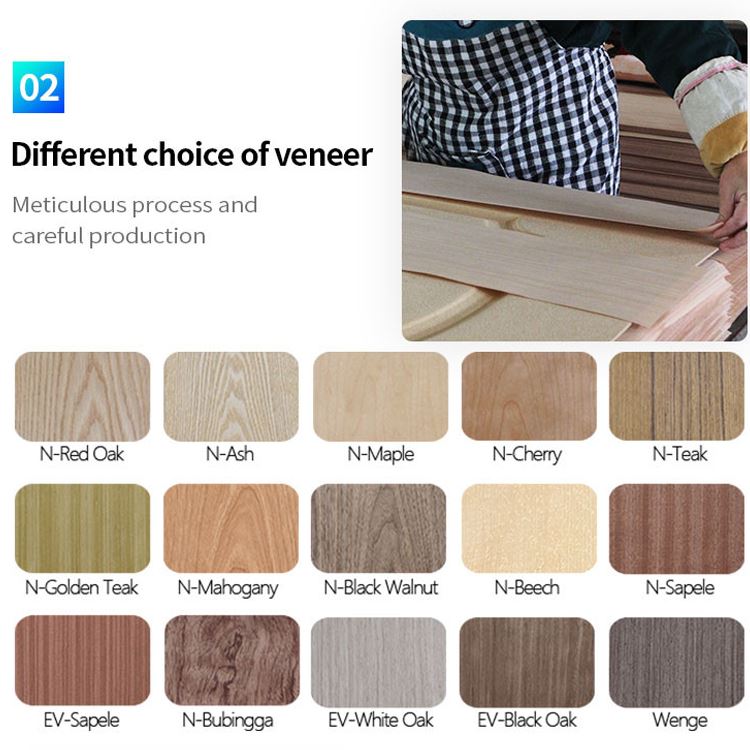

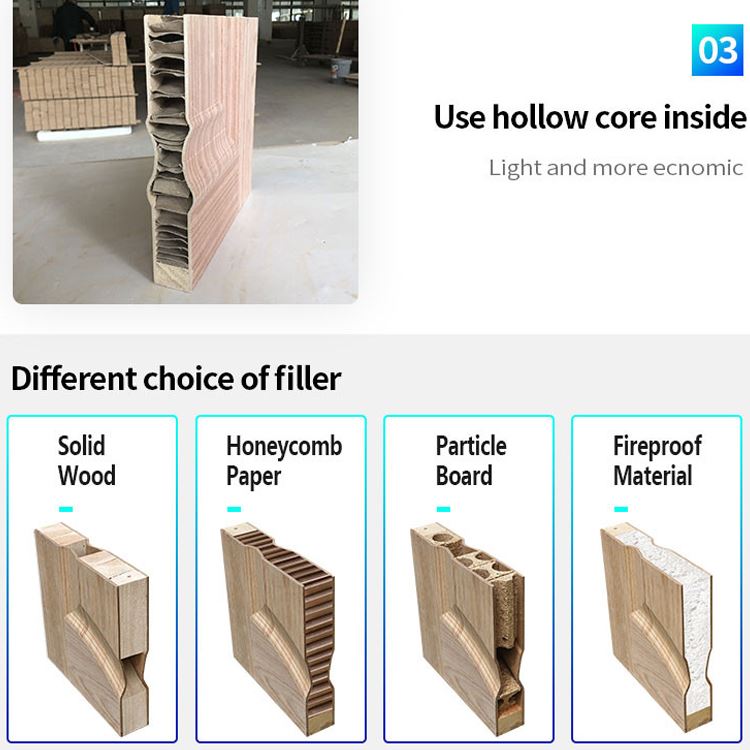

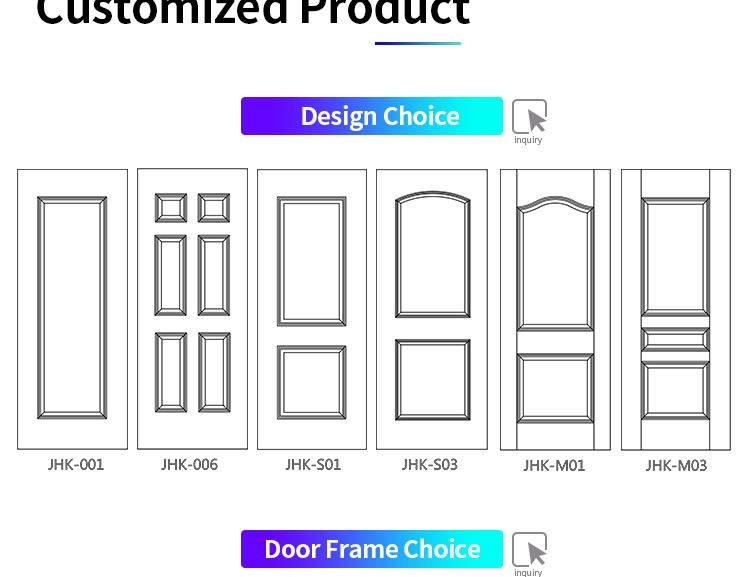

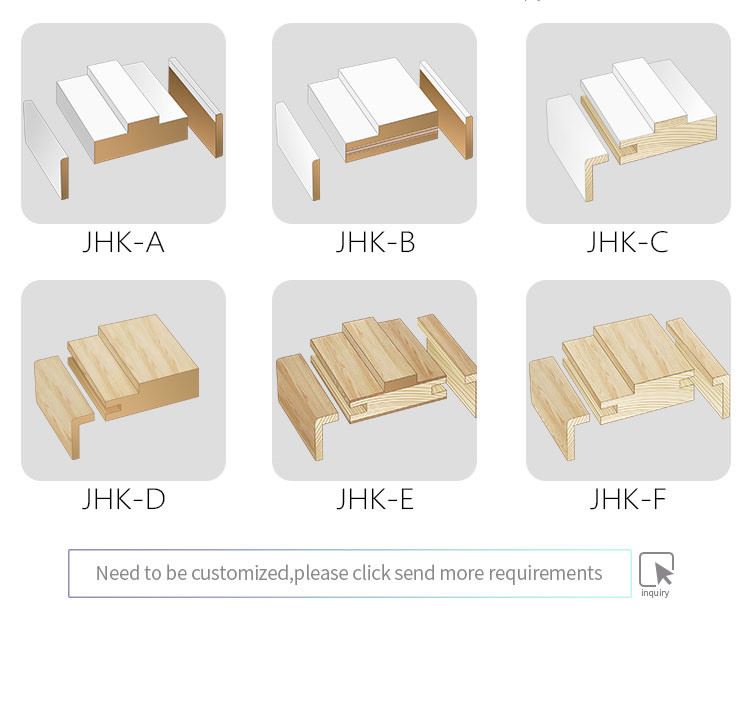

JHK-004 4-Panel hollow core interior veneer door consists of HDF and veneer, about the surface, you can choose the Oak, Teak, Ash, Sapele, Maple, Walnut, Beech and so on. The modern high tonnage vacuum molding machine, high pressure heat in the environment, there is twice molding to make sure the high quality. These door skins are manufactured using quality wood from good managed forests.

Maple is not only a wonderful flower in the natural landscape, but also a good material for architectural decoration. That’s color is harmonious and unified, often used in making fine wood furniture, high-grade furniture, in the cork gluing sandwich panels, wooden shovel and also has a wide application in paper industry, other USES include: veneer, wood frame, lamps and lanterns, drawer sides, interior construction, complete sets of furniture, tables, locker, baseboard and cutting products. With this breed of pavement ground, comfortable, gentle, bright, generous.

FAQ:

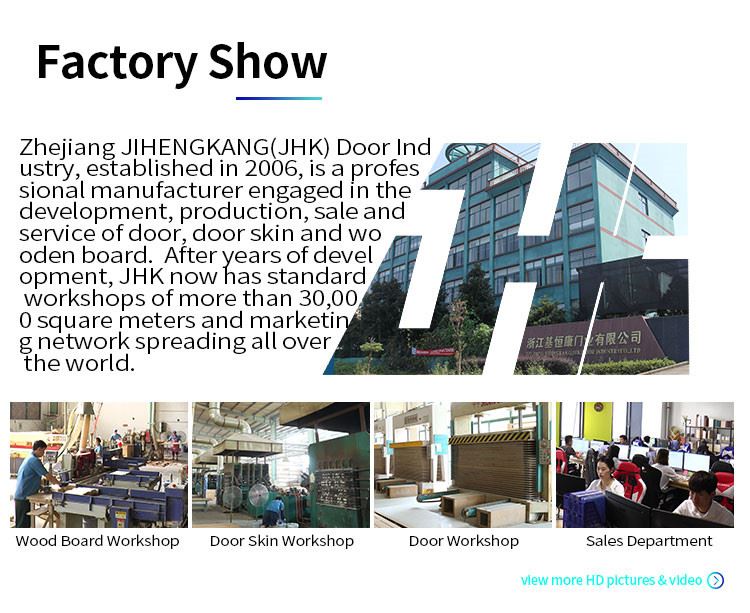

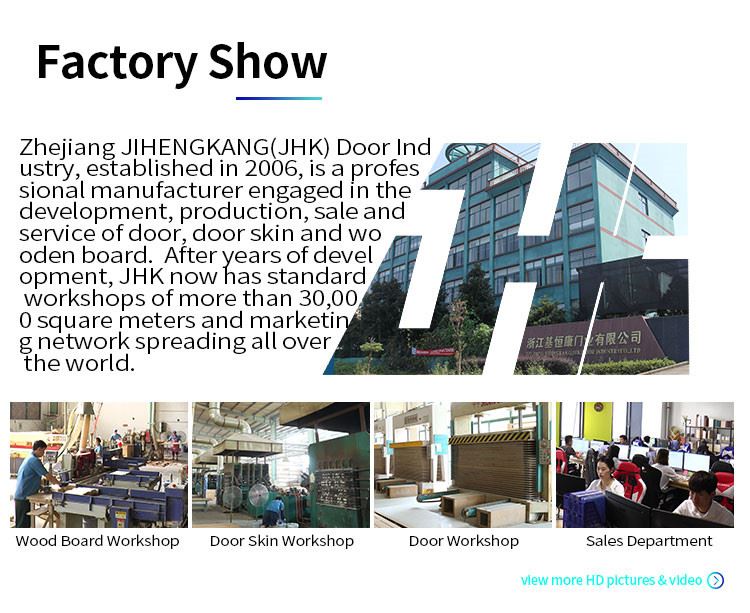

1. When did your company establish?

JHK: Since 2000, we are a manufacturer with 15 years’ experience.

2. How many people work in your company?

JHK: About 500 People.

3. What is the capacity of production per year?

JHK: More than 500,000 PCS.

4. What raw materials of wood do you have?

JHK: Natural wood and EV wood are both available. Red oak, ash, teak and mahogany are our recommended materials.

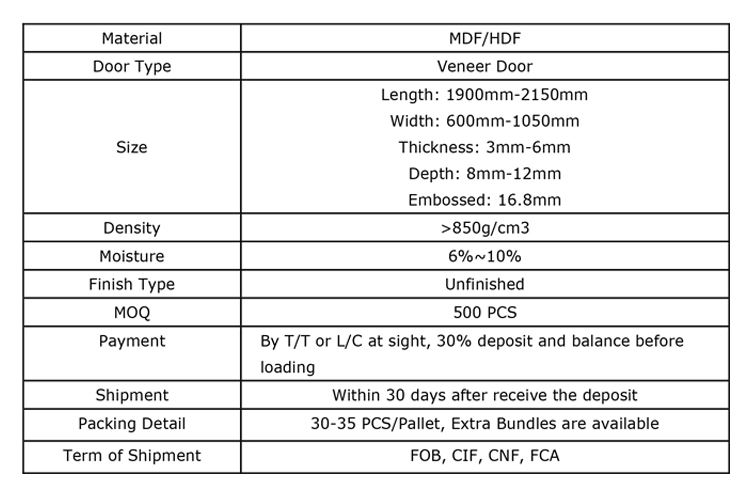

5. What is the MOQ?

JHK: One 20’ container, which can hold 2500-3000 PCS door skins. Sample order is also available.

6. What is the delivery time?

JHK: It will be around 40 days after receiving the payment.

7. Can I visit your factory?

Yes, of course! We are very welcome for your visiting, and we will pick you up at the YIWU airport or the Jinhua railway station.

8. How about your after-sale service?

JHK: We guarantee our customers one-year warranty, and will deliver forever service no matter before or after the sale.

JHK-004 4 Panel Hollow Core Interior Veneer Doors

JHK-004 4-Panel hollow core interior veneer door consists of HDF and veneer, about the surface, you can choose the Oak, Teak, Ash, Sapele, Maple, Walnut, Beech and so on. The modern high tonnage vacuum molding machine, high pressure heat in the environment, there is twice molding to make sure the high quality. These door skins are manufactured using quality wood from good managed forests.

Maple is not only a wonderful flower in the natural landscape, but also a good material for architectural decoration. That’s color is harmonious and unified, often used in making fine wood furniture, high-grade furniture, in the cork gluing sandwich panels, wooden shovel and also has a wide application in paper industry, other USES include: veneer, wood frame, lamps and lanterns, drawer sides, interior construction, complete sets of furniture, tables, locker, baseboard and cutting products. With this breed of pavement ground, comfortable, gentle, bright, generous.

FAQ:

1. When did your company establish?

JHK: Since 2000, we are a manufacturer with 15 years’ experience.

2. How many people work in your company?

JHK: About 500 People.

3. What is the capacity of production per year?

JHK: More than 500,000 PCS.

4. What raw materials of wood do you have?

JHK: Natural wood and EV wood are both available. Red oak, ash, teak and mahogany are our recommended materials.

5. What is the MOQ?

JHK: One 20’ container, which can hold 2500-3000 PCS door skins. Sample order is also available.

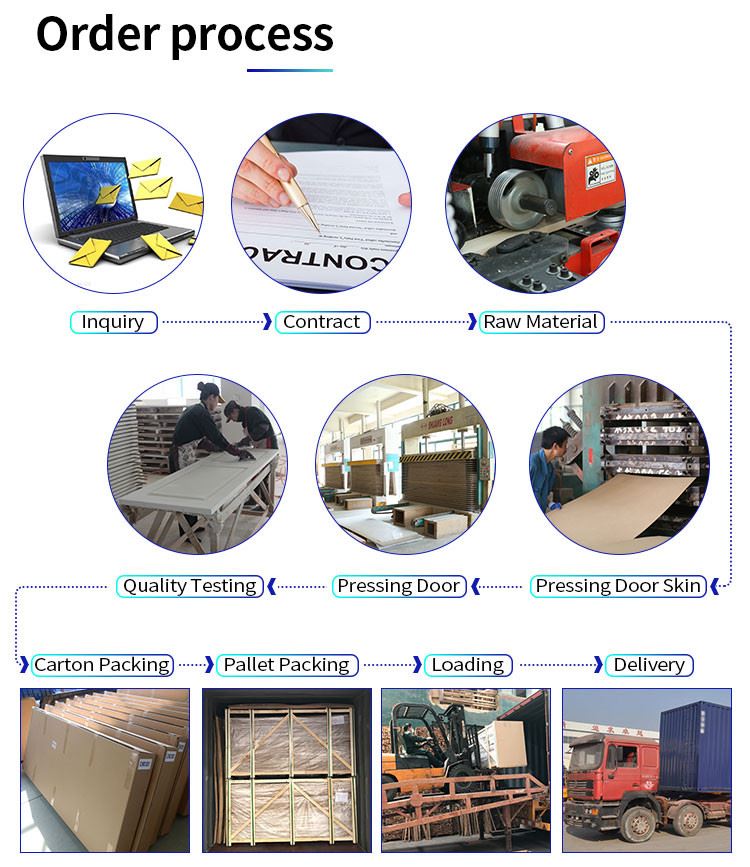

6. What is the delivery time?

JHK: It will be around 40 days after receiving the payment.

7. Can I visit your factory?

Yes, of course! We are very welcome for your visiting, and we will pick you up at the YIWU airport or the Jinhua railway station.

8. How about your after-sale service?

JHK: We guarantee our customers one-year warranty, and will deliver forever service no matter before or after the sale.