| Quantity: | |

|---|---|

JHK-P05 Pretty Door Plastic Entry wood PVC Door

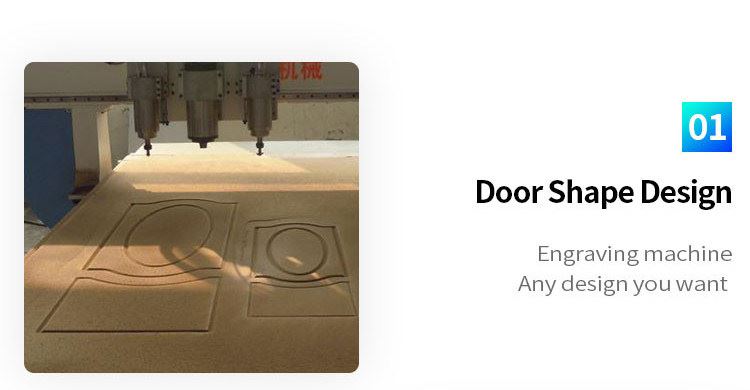

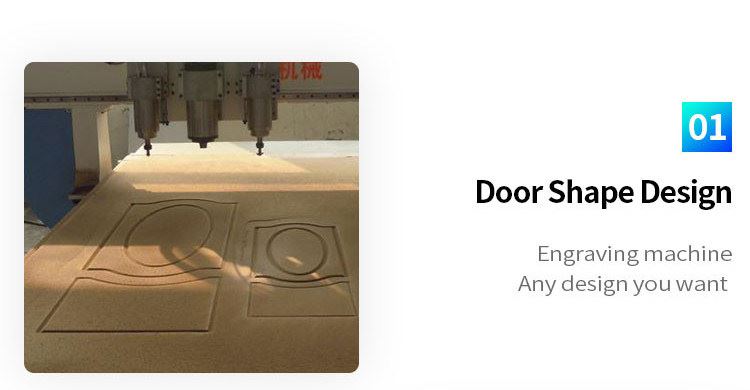

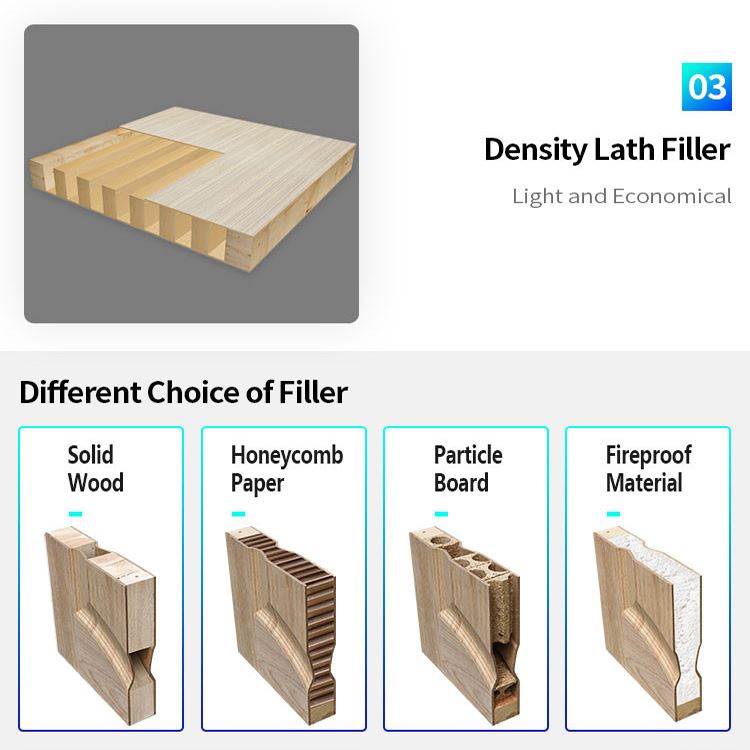

The PVC Door surface board of a molded door, whose concave and convex surface is not realized by means of engraving and milling type, is thin in thickness, material saving, low in cost and strong in stereoscopic sense, and will not pollute the environment because of engraving and milling type processing and fiber dust.

The technical scheme adopted by the utility model to solve the technical problems is a PVC veneer molded door panel, including the panel and PVC leather, the feature of which is that the panel is a board with concave and convex molded and PVC leather is covered on the panel.

When implemented, the thickness of the panel is 2-4mm.

In practice, the fiberboard is a two-layer composite structure fiberboard.

Making PVC molded facade of this practical new type plate process has many steps to make sure PVC Door quality.

FAQ:

1. When did your company establish?

JHK: Since 2000, we are a manufacturer with 15 years’ experience.

2. How many people work in your company?

JHK: About 500 People.

3. What is the capacity of production per year?

JHK: More than 500,000 PCS.

4. What raw materials of wood do you have?

JHK: Natural wood and EV wood are both available. Red oak, ash, teak and mahogany are our recommended materials.

5. What is the MOQ?

JHK: One 20’ container, which can hold 2500-3000 PCS door skins. Sample order is also available.

6. What is the delivery time?

JHK: It will be around 40 days after receiving the payment.

7. Can I visit your factory?

Yes, of course! We are very welcome for your visiting, and we will pick you up at the YIWU airport or the Jinhua railway station.

8. How about your after-sale service?

JHK: We guarantee our customers one-year warranty, and will deliver forever service no matter before or after the sale.

JHK-P05 Pretty Door Plastic Entry wood PVC Door

The PVC Door surface board of a molded door, whose concave and convex surface is not realized by means of engraving and milling type, is thin in thickness, material saving, low in cost and strong in stereoscopic sense, and will not pollute the environment because of engraving and milling type processing and fiber dust.

The technical scheme adopted by the utility model to solve the technical problems is a PVC veneer molded door panel, including the panel and PVC leather, the feature of which is that the panel is a board with concave and convex molded and PVC leather is covered on the panel.

When implemented, the thickness of the panel is 2-4mm.

In practice, the fiberboard is a two-layer composite structure fiberboard.

Making PVC molded facade of this practical new type plate process has many steps to make sure PVC Door quality.

FAQ:

1. When did your company establish?

JHK: Since 2000, we are a manufacturer with 15 years’ experience.

2. How many people work in your company?

JHK: About 500 People.

3. What is the capacity of production per year?

JHK: More than 500,000 PCS.

4. What raw materials of wood do you have?

JHK: Natural wood and EV wood are both available. Red oak, ash, teak and mahogany are our recommended materials.

5. What is the MOQ?

JHK: One 20’ container, which can hold 2500-3000 PCS door skins. Sample order is also available.

6. What is the delivery time?

JHK: It will be around 40 days after receiving the payment.

7. Can I visit your factory?

Yes, of course! We are very welcome for your visiting, and we will pick you up at the YIWU airport or the Jinhua railway station.

8. How about your after-sale service?

JHK: We guarantee our customers one-year warranty, and will deliver forever service no matter before or after the sale.