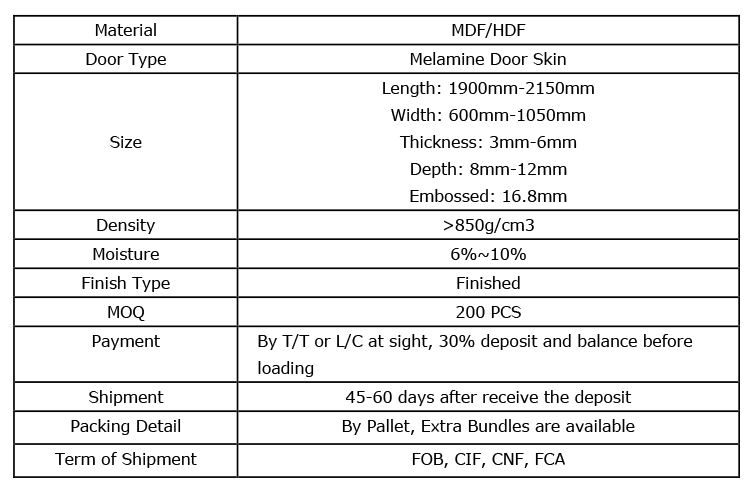

Melamine is considered, and often referred to as, a direct or low pressure laminate (LPL) because it is manufactured with a pressure of 300-500 pounds-per-square-inch. Layers of paper are saturated with a melamine resin until they are converted into a solid, plastic surface via thermal fusion. The melamine sheets are molded together as one of the layers of plastic laminate, which is then bonded together with particleboard or to another backing material to create a durable plastic sheet, which is what is used to give products such as Formica an attractive surface.

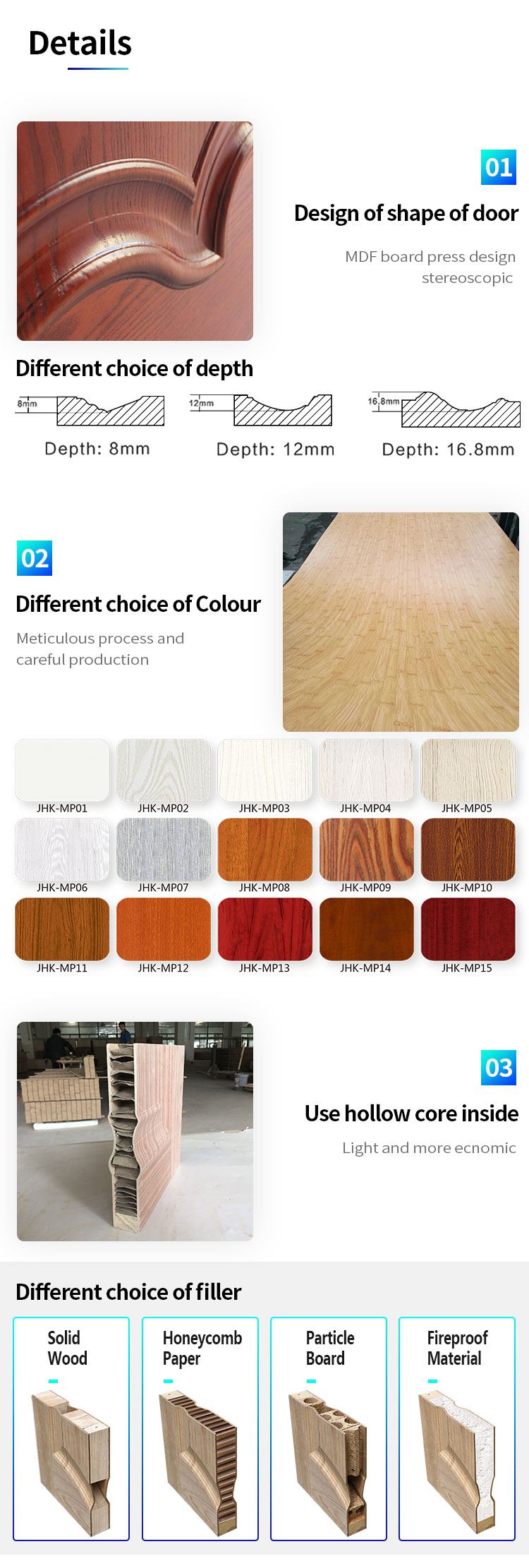

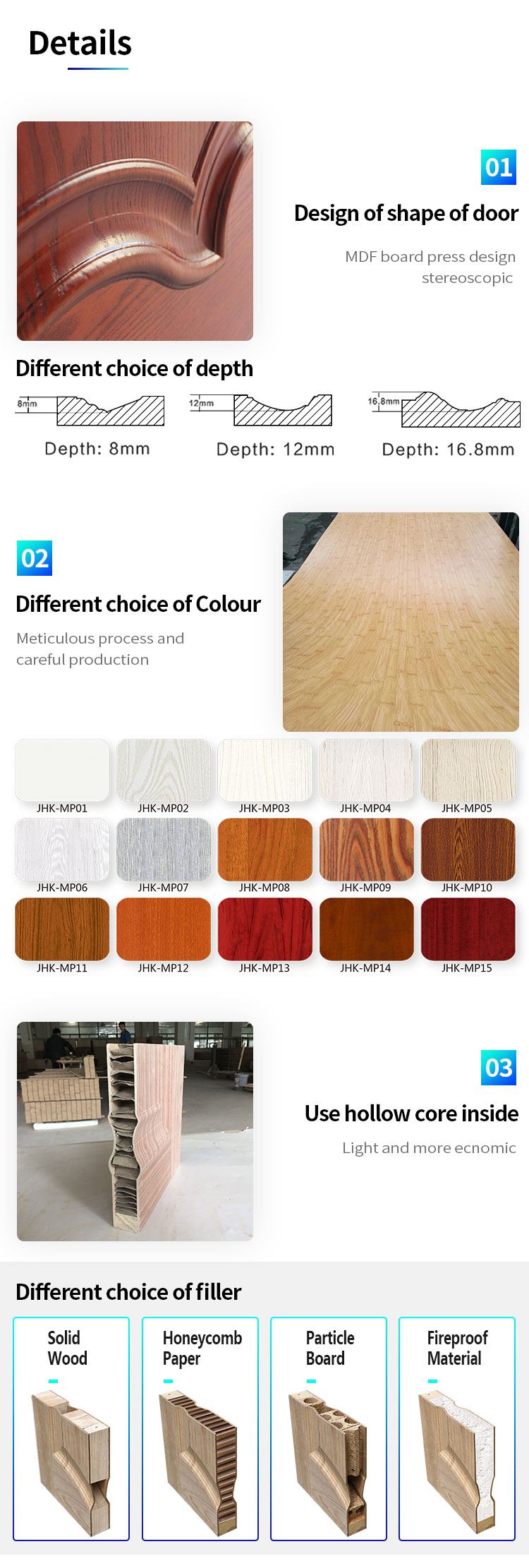

Available in a wide selection of textures and natural wood grains, melamine panels are a cost-effective, multipurpose option for adding color and finishes to designs and projects. Generally sold already attached to the particleboard, melamine is durable, scratch and shatter resistant, and waterproof. Granted, while the material itself is waterproof, if water gets into the particle board underneath, it could cause the melamine to warp. Additionally, even though melamine is very sturdy, if it’s not installed properly, the particle board can bear damage and cause the melamine to chip. Because it has voids on the ends, melamine will require an edge-banding to cover the area. Projects constructed with melamine generally have up to a five-year lifespan.

Melamine is considered, and often referred to as, a direct or low pressure laminate (LPL) because it is manufactured with a pressure of 300-500 pounds-per-square-inch. Layers of paper are saturated with a melamine resin until they are converted into a solid, plastic surface via thermal fusion. The melamine sheets are molded together as one of the layers of plastic laminate, which is then bonded together with particleboard or to another backing material to create a durable plastic sheet, which is what is used to give products such as Formica an attractive surface.

Available in a wide selection of textures and natural wood grains, melamine panels are a cost-effective, multipurpose option for adding color and finishes to designs and projects. Generally sold already attached to the particleboard, melamine is durable, scratch and shatter resistant, and waterproof. Granted, while the material itself is waterproof, if water gets into the particle board underneath, it could cause the melamine to warp. Additionally, even though melamine is very sturdy, if it’s not installed properly, the particle board can bear damage and cause the melamine to chip. Because it has voids on the ends, melamine will require an edge-banding to cover the area. Projects constructed with melamine generally have up to a five-year lifespan.